|

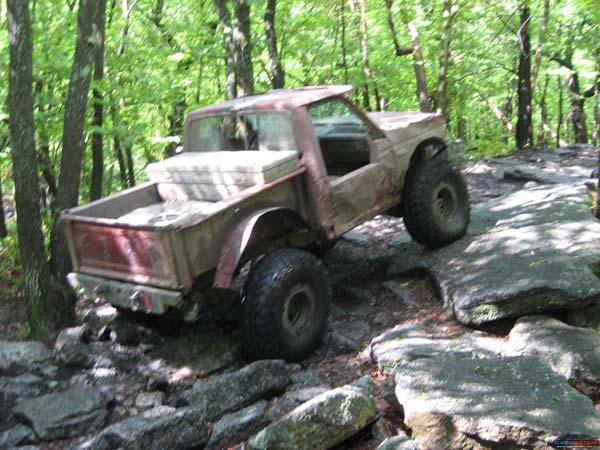

At the junkyard; check out this awesome bucket van we found! ...and a p/u with a pretty cool rattle can paint job So it tooks some time but its finally done. It goes like this: Called my buddy Eric from EMS Offroad about getting a new axle. (for those that dont know why i needed a new D60, read this) He said he'd hook me up, and wed build something that shouldnt break. So thats what we did. Its a brand new Currie Rock Jock center section. Ya know the one, with the diff cover rotated back, which coincidentally adds 3/4" of ground clearance, even with the little bolt-on skid plate. It uses two large pinion bearings instead of the smaller outer bearing, along with a bigger pinion seal. The tubes are 3.5" DOM machined to fit the Superduty diff seals. Stock inner Cs & knuckles, with some plating in key spots. Cage's weld-on brackets, and of course a truss to help keep everything together. We kept the same caster angle i had, while rotating the pinion up 5º for a better dshaft angle. I had to get a new long-side inner shaft, as well as the ring-side half of the ARB case, since that bent when the housing broke, altho everything else survived. So now, onto the Pics! ....some of which suck, but hey, i think i did pretty good for a digicam with a broken lcd screen! Lower coil mounts going back together radius arms. Check that pinion angle! But the truss is closer to the xmember than it looks new lower tracbar mount axle is in! working on steering: ...and finally done! check that awesome pinion angle parked in the yard, ready to go wheelin! This was a rough day of wheelin for me & ox. Pretty early on, Ox broke an upper link mount on a hill climb. Later in the day, i broke my D60 completely in half! So here's what happened. I had just gone thru Smoothie & Milkshake, RC's nastiest mud holes, when i spotted the housing was cracked. There arent any rocks in those pits, so it must have been coincidence that i decided to look at the front, and see the tube sticking out about an inch. Well, i had a ratchet strap around both radius arms, but it didnt last long....about 1000' later the front-end just fell apart. Probably a good thing i was only idling along in 1st when it happened. A bunch of Toyota guys from Right Coast 4x4 (whom me & ox wheeled with the previous day) helped to get it back together so i could drive it out and get it on the trailer. As you can see, the passenger inner axleshaft is bent. So is the ring-side trunion on the ARB as well, so we're going to have to replace some parts on that too. Hadnt been out in a while, so me & ox decided to take a trip to Rausch Creek Pizza Rock! This area isnt what it used to be, since it got logged. I only took a few pics during the day as we were pretty mobile, but Ox got some more, which you can see over on FSB. Ok so lets go into some theory. Keep in mind, this is just that; im no expert on the subject, just that ive spent a good amount of reading on the subject prior to building mine, and as it turns out, it works well.

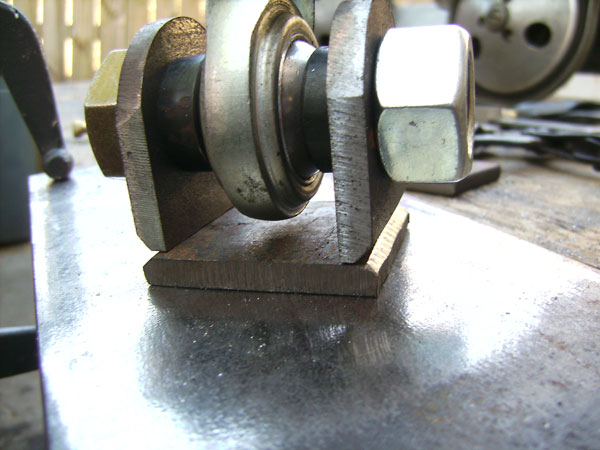

The anti-wrap bar acts as a lever for your trucks rear suspension. Since the springs cannot wrap under load, the force is directed along the anti-wrap bar. Under load the pinion wants to deflect up, but it cant due to the bar being mounted to the frame. So, when the bar swings up, it pulls up on the frame, which lifts the rear of the truck up. At the same time, an equal and opposite force is pushing down on the rear tires. So as the truck lifts up, you gain a lot of down-pressure on the rear tires. They squat down a bit, dig into the ground harder, and off you go. This is referred to as anti-squat (AS), and is usually measured in %'s. There is no right % for it to work perfectly as its all in driver preference, but you dont want too much, or youll end up with a vehicle that has a lot of rear wheel hop, which IMO is just as bad as spring wrap. So id shoot to minimize it best you can, since youll never get it to 0% on a lifted vehicle. No matter what, youre gonna pick up AS, and its gonna lift up. Get used to it. So, there are ways to tune this to your advantage. #1 is bar length. The longer the bar is, the less AS you gain. The angle at which the bar meets the frame is also important. The steeper it is, the more it will lift the frame. Unfortunately with a lifted truck, theres not a whole lot you can do about this part, as youre gonna get lift out of it. Remember you measure the bar angle by drawing an imaginary line down the middle of it, dead center between the two fixed points at the axle. I have read to make this match the driveshaft angle, but there is no theory behind why. It seems more like, thats the way most end up, so thats the way people do it. The shackle angle plays a small part too. At 90º, it has no effect. But, put the frame-side mount further forward, and it helps to decrease the lift gained from the bar. Angle it backwards towards the axle and it will lift more. My recommendation, set it 90º, or slightly forward (say, plus/minus 5-10º?). Keep in mind, this is assuming you have the shackle in tension (like i do), which means the anti-wrap bar goes above the shackle, not below. If you have the bar go below the fixed point for the shackle, then reverse the above info. Either way, dont go too far, as you need to make sure the shackle will not go into a bind when you cycle your suspension. A stock-height truck, the bar will be flatter and have less AS, but under a lifted truck you could only accomplish this by lowering the frame mount way down, potentially into harm's way offroad. Id rather have it lift a bit, then get it caught on rocks all the time. As for which side of the vehicle to put it on, the theory is that, under load, the rear driver plants harder than the passenger. This is because of the rotational force of the pinion, creating a lifting effect on the passenger tire. Ive read many places that putting the bar on the passenger side theoretically combats this, but in regards to controlling spring wrap, it makes no difference which side of the diff it is on. So since it does its job equally effective on both side, i put it where i had room, which was the d.side. On the pass side most of us have an exhaust system that would be quite difficult to get to fit back under there once an anti-wrap bar is installed. There is one other thing i want to add. This is that an anti-wrap bar puts a big load on the axle tube, so it is highly recommended to weld your tubes to the diff, or you could potentially bust the plug welds and spin a tube. Read about it & seen the pics, so i welded mine. So far so good. So i took some time last month designing and building an anti-wrap bar for the 88. Here's the final result: On the axle tube, im using brackets from Blue Torch Fab. The bar/shackle is using 3/4" rod-ends from Aurora, which i got at a local bearing house. The bushings at the axle end i bought from Poly Performance. The bar is made of 1 1/4", .120 wall tubing, which the weld-in bungs fit perfectly. In order to make the lower tube more dent-resistant, i got a piece of 1" barstock and cut it down to fit inside the tube. I doubt that sucker is gonna bend! I built a shackle for the frame-side end to use shackles at both ends, so i dont have binding issues: For the frame side, i made a crossmember that spans the frame The shackle connects to it via a bracket i made out of a scrap piece of 2x4 box tube: The final result is tucked up in there pretty tight and out of harm's way, but its also built beffy enough that it can take some abuse w/o concern of any damage: The bar ended up ~40" long. The shackle is ~6", and there is 6" of vertical separation on the axle mounts. The shackle is pretty close to 90º, and while i could probably make some adjustments to the two heims to get it there, i dont think i will bother. There is some lift to the nose, but its minor. The big difference is now when you get on the throttle, she digs in and goes! No more spring wrap or axle hop at all. Earlier in the month i built a set of extended shackles for the rear of the bronco. Im extending them 2", so i cut some flat stock 6 1/4" long, by 1 5/8" wide. Spaced out 2" from the OEM hole, welded it to the flat 'ear', and then hammer the other end over till it touches the body of the shackle. Then just clamp it and weld it up. I tacked the plate to the shackle via the original bolt hole to hold it in place, and then once the sides were fully welded, plug welded the original bolt hole and ground smooth. Small tabs made to fill in the gaps so the shackle still has the same ID, and its nice and beefy After all that was welded & ground, i added in a brace in the middle to keep the ears from bending: ...and the finished product! With the longer shackle i moved to the rear hole on the hangar, and now weve got a good shackle angle again: So i did this in conjunction with moving the front spring hangar 3" backwards, installing new non-bent mainleafs, and removing my 2" AAL to get back to stock-ish springs. The end result was a success, as the rear suspension definitely works a lot better now. Decided to go to Rausch Creek over the weekend with a few buddies. It was a day full or carnage! We went to "O" Trail first, where Keith immediately blew both beads: Ox playing on a rocky hill climb on "O", this is right at the section where i bet Ox to run it from the passenger seat last time These were some big rocks The view from the new Green rated trail J1 Ox: Keith: Steve: Jim: One of the few pics i have of mine couple turns later, keith is stuck quick tug from steve and keith is free to continue on RIP steve's transmission Ox was in the lead, so he got to pull steve the rest of the way outta the trail. Oh no! Fortunately only the outer bead popped so it was relatively easy to re-seat. After much winching & pulling to get steve off the trail, and then after we loaded steves back on the trailer, we headed back in. Ox playing on a hill right near 'The Gauntlet', one of the comp courses ...and stop Probably coulda got free if the dshaft wasnt sitting on that boulder Keith to the rescue! Me coming up on the climb to the right, while Ox gets free ...and back onto the trails sidehilling, but its lost in the pic, other than the way the tire is rolling under the wheel Thats pretty much all i got. We got in some decent trail time, just didnt have the usual photographer (my brother) runnin around snappin pics. There is a thread over on FSB that has more pics from of the trip. My drivetrain held up, but the body wasnt so lucky. The half door. You can see i hit the cab corner too Couldnt get the door open cuz it bent around the striker. Put the full door on and couldnt get it to close- to make a long story short i bent the corner of the cab to the point that the striker bolt moved in a full inch! I was only able to get the bolt adjusted out 3/4", so you have to slam the door to get it to close. The a-pillar: ...and finally, the trans pan: Bent so far up that this happened: it would slip when shifting from 1 to R, when on an incline. I wonder why! Fixed the pan, threw a new filter on, and she is good to go again! Got some free time, so heres some more pics! At that point it was 4pm, so we said screw it and headed back to camp. Unfortunately, the next morning my radiator sprung a leak, so that ends our wheelin pics! There is still a ton i didnt post, so if youre interested, here are the galleries: Friday // Saturday. |

Categories

All

Archives

February 2026

|