|

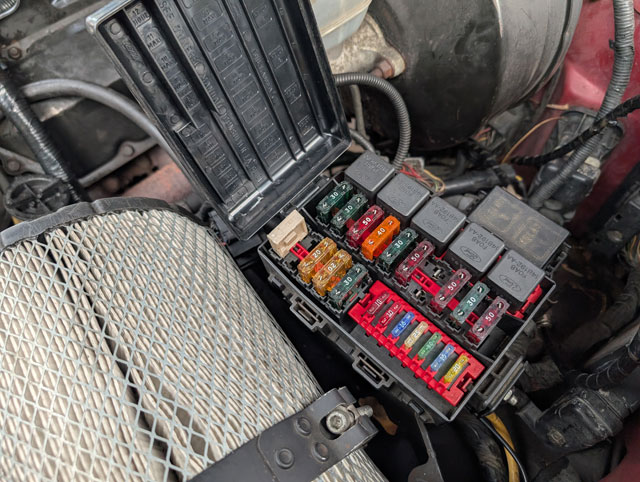

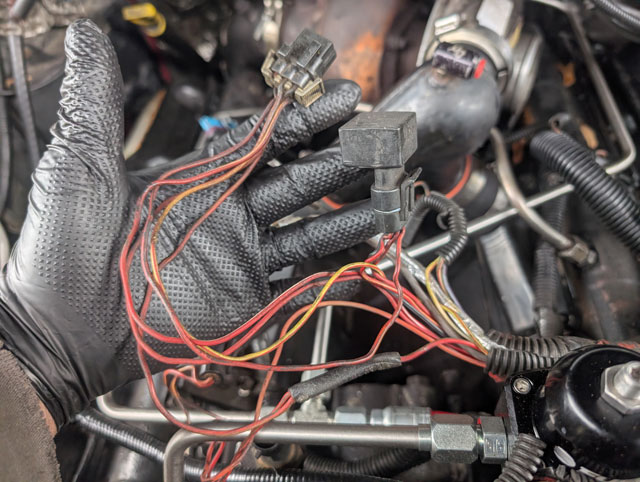

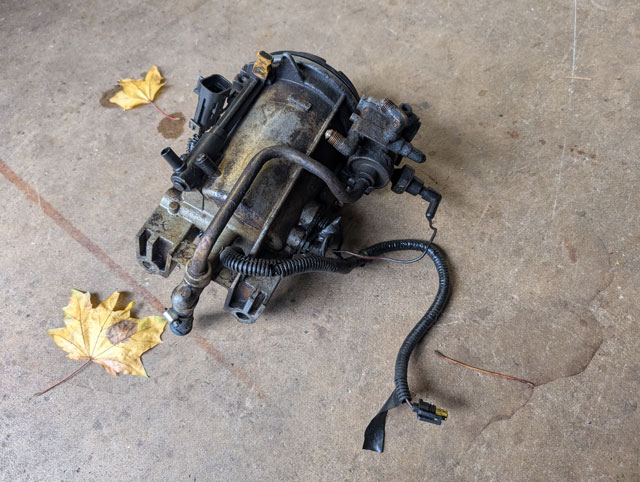

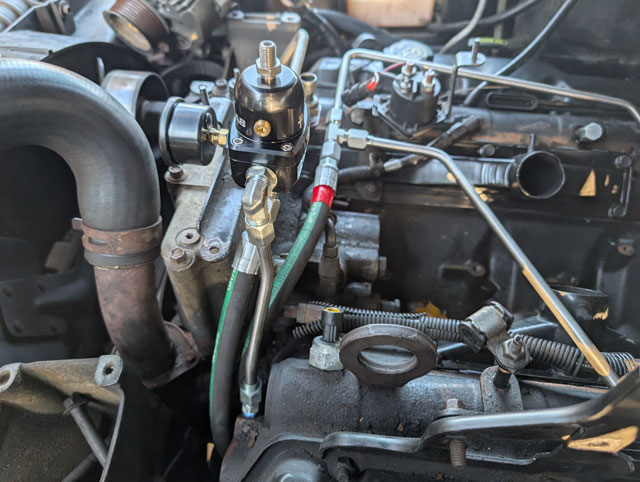

Rausch Creek! Joe: Joe Sr: Ox: PXL_20251122_202236042.jpg PXL_20251122_170558488.jpg PXL_20251122_174644129.jpg trail_f.jpg PXL_20251122_150939407.jpg PXL_20251122_151215846.jpg PXL_20251122_203406136.jpg PXL_20251122_163113763.jpg PXL_20251122_202940250.jpg I sheared off a brake line adapter on the rear axle and i bent the crap out of my steering so ive got to fix that too Epic day of wheeling. I dont really know where to start, but there was lots of video shot, so at some point in time myself or Joe will probably get a video put together. The diesel ran incredible, im guessing ive had a big boost leak for a long time because boost is up and EGTs are down. Well worth all the headaches! Buttoning up loose ends. Here's the connector for the fuel selector valve with the loom stripped away The only thing i need to do is splice the Y/LB into the Y/W The DB/Y is the signal wire from the front tank float, and the R and Br/W come from the switch, but i have the switch unplugged in the dash so those are dead at both ends now. So then i just fixed the loom and now it looks like i never had a front tank Got some fittings cobbled together to fix the water/meth injection. Not pretty but itll do for now until i can come up with a cleaner looking solution ...and then i ran around like a chicken with my head cut off packing tools and spare parts, hooking up the trailer and loading up for tomorrow! Here's hoping we have a good day tomorrow! Picking up where we left off, engine harness is now reinstalled The second i touched the glow plug relay it broke; thankfully Napa had one in stock so thats already fixed Fuse box is now reassembled and looking like i never touched it After some research on oil filters, i opted to switch to the Fleetguard oil filter, p/n LF9027 Some interesting stuff going on in there. If youre not familiar with this filter, it is a standard 30 micron filter, with a 5 micron bypass filter built into the bottom. Its a good way to get bypass oil filtration, without having to install a big bulky bypass filter system on the engine. That was the last item, nothing left to do but to turn the key and see if it would start.......and it did! The fuel gauge is reading past full, so the circuit must be open. I guess it ties into the selector valve on the frame rail. Got the book in front of me, going to try to figure that one out tonight so i can rewire it tomorrow.. Went for a test drive and it ran great! Havent driven it in a month so its hard to say, but id swear it spools faster than it used to. I mean, it should as i had a pretty big leak on the driver up-pipe, but man it runs good now. I gave it a good thrashing on the freeway and got it to 32-33 PSI pretty quickly before i let off. Just did a quick 5 minute drive and came back to check stuff. Almost had a mini heart attack, i thought the valley was full of fuel! Its not though, its water. Pulled the water/methanol nozzle out of the intake to test the system and found the adapter fitting for the nozzle is leaking Closer inspection shows the fitting is split in half So tonight at work im going to scrounge up some fittings to see what i can find to get it hooked back up, because i would really like it to be working for saturdays wheelin trip, and then ive got to get the fuel gauge working. So very close to being done! What is with the damn deer this year?!!! Hit another one last night. 30 seconds from the parking lot at work, small doe ran down the side street and hit the side of the bronco No major damage thankfully I dont remember this dent in the door being here Definitely hit it with the tire Coworker was right behind me, said the hit killed it instantly. Pretty sure one of my coworkers took it actually. I wasnt hauling it home in the back of the bronco, thats for sure! Accessory drive is all back together, and i reloomed and ran the harness for the Alternator and a/c compressor The rest of the engine harness comes from the driver side, and is a bit of a mess. Broken loom, disintegrating tape, etc. Pulling the engine harness apart, i can eliminate all this crap The square plug goes to the fuel bowl, and that module is the WIF module, which i dont need anymore Looking at the fuel bowl, i can eliminate this entire companion harness Except, oh wait, i cant, because the pigtail for the IPR is in here. This whole harness is pretty well shot: Kinda surprised i didnt have any issues with how bad it is Plan is to take the pigtail for the IPR out of that harness and splice it back into the main harness so i can clean up the whole harness a good bit. Anyways, main harness is stripped, all this junk can go: Everything i dont need removed. Tomorrow i will begin cleaning this up and re-looming it for reinstall Progress! Next thing i needed to do on the diesel was run fuel lines. So heres what i came up with. I started with the original lines at the fuel tank I didnt use the full length, i cut them off just a foot or so up the frame rail near the shock mount, flared them for a standard fuel line disconnect, and ran the 3/8" Parker Pushlok hose the Irate fuel kit came with: Fuel pump/filter housing now plumbed. I didnt like how close the fuel hose was to the transfer case so i added a 45º on the outlet side to help it stay away I ordered a kit for a single tank truck, not thinking that the single tank trucks run the front tank and im running the rear. So it was a little short on fuel hose. My remedy was to made a bracket that fits the frame rail here, and then add a set of 45º bulkhead fittings. Gives me a place to end the Parker hoses, and helps get the forward fuel lines to clear the RABS valve: From there i laid out some hose, figured out routing and length, and made some hoses: ...and landed at the new fuel rail With that done, it was time to hotwire the pump and check for leaks ...and 65 PSI attained with no leaks! Turbo going back in Turbo finished, HPOP crossover tube reinstalled, and new intake boots installed. We're getting close now! |

Categories

All

Archives

February 2026

|