|

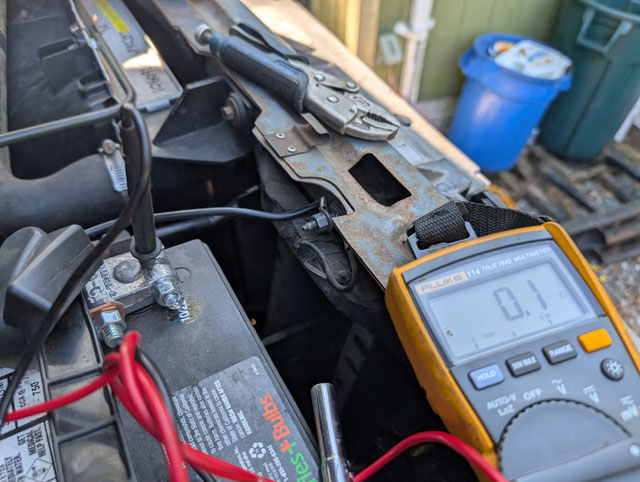

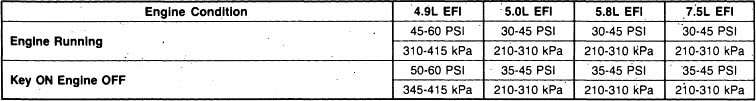

So i drove the wife's 90 to work the other day, and no CEL. Thinking about driving it in again tonight just to get another couple drive cycles on it before i call it fixed. Moving on, im back to work on the F250. Gotta get the pyro probe issue resolved. The steel fitting the probe is held in with. Its pretty crusty, and that little set screw is probably never coming out. Got the brass reducer bushing off, and drilled out the set screw best i could. Its rotted enough that neither standard nor metric allen keys fit it properly anymore so not much choice there Soaked it in penetrating oil for 5 days, then tried one of those magnetic induction heaters for removing crusty bolts and nuts; it works pretty good, but the fitting has become one with the probe. Ended up cracking the thin outer wall of the probe, so now i have to replace it. I guess i cant complain too much, it is ~15 years old at this point. Moving into the interior Autometer GS Series is a stepper motor gauge, which means one fancy plug for everything instead of multiple for power, sensor, etc Pretty sure i can just pop the pins out of the plug for the probe, so i dont have to cut & rewire the gauge harness GS series uses temp probe p/n 5251, which doesnt include the fitting, which is kind of lame. However, the manifold fitting they sell for it is not that dumb one with set screw, its a swagelok 3/16 compression fitting. Im not paying $59 for a compression fitting though, so i ordered one elsewhere, which i already have actually. So tomorrow im going to get the fitting installed in the manifold so whenever my new probe comes i can just slap it in and call this project done. Dont have a DMM that can test Hz so i couldnt test MAP function. But i figured id still test for power and ground. Power was good, but my ground reading was off a bit what the f-? I was caught so off-guard by that i actually performed the test several times, with several meters! Then i took everything apart and cleaned the ground. Much better: This was one of the main harness grounds, so now im wondering if this was the problem the whole time. Tomorrow im going to clean & reinstall the spark plugs, and temporarily bypass the vacuum cannister since i dont have a good spare. Then maybe ill take it for a drive and see if anything changes. Holy cow, when it rains it pours. Ive got a fleet of vehicles that decided they want attention, all at the same time! So friday the green bronco popped a P0707, transmission range sensor. That's an easy one, order a new MLPS, which i just got and installed this morning after work. So that's one fixed. So i was driving the diesel all weekend; well last night it decided to blow the temp probe for the pyro out of the manifold! This is probably going to suck to fix. There is a little tiny set screw in the fitting that locks the temp probe in place, and after 15 years its pretty well seized in there. Got it soaking currently, hoping i can get it to free up and come off the probe. If not ill cut it off the probe and worst case replace the probe. We'll get back to this after a couple days of it soaking in penetrant. So i drove the wife's 90 to work last night, and of course its running rich and popped a CEL Pulled codes, all i got is a 42, system rich. Swapped the MLPS on the green one while i waited for this one to cool off, then pulled the plugs. Yup, its running rich! Every plug is covered in soot, except for #4 Check fuel pressure (chart for reference) KOEO - 40 PSI. KOER - 36 PSI. Unplugged FPR and it jumped to 42 like it should. No fuel in vacuum line, and the system doesnt bleed down. So i decided to look at the vacuum lines even tho theyre all new from a couple years ago; all good. I pulled the steel vacuum cannister off the bracket and spotted this So either this was leaking the whole time, or i caused it when i took it off the bracket. Either way, i cant see why a vacuum leak in between the manifold and the EVR solenoid would cause a rich condition. And it never threw an EGR code anyway. Out of time for the day though, so will continue looking at it tomorrow. I made the terrible mistake of going on marketplace, where i found a soft top for a bronco, in great shape, for $200! No instructions and missing some hardware but i think we can figure it out, so yesterday me and the kiddo sorted it all out and got it installed. Friday i pulled the half cab off ...washed the mud out of the inside... ...and reinstalled the back half of the interior! So yesterday me & the kiddo started laying out the rails to figure out how it goes together He was super excited about the project and started laying out parts Bedside rails in. They bolt to the original hard top captured nuts altho you have to drill a couple extra holes & put an extra couple screws in to hold it a little more secure Sorting out the top rails: They are supposed to be held in place with these stainless sheetmetal screws but im missing about half ...fortunately i have a ton of oem body hardware, so i used some oem sheetmetal screws instead Top rails installed: working on the tailgate rail: It doesnt actually attach to the tailgate, it attaches to the siderails using studs & wingnuts (for easy removal). But it s supposed to have some kind of seal here i had some random weatherstripping in the shed, thought it might work but its not big enough to fit over the lip for now foam will have to do, ill have to reach out to Broncograveyard during the week to see if i can buy the correct seal Sorting out the bows. The fabric sleeves for the bows are also missing, maybe i can get them too. ...stretching out the top... ...and done! I think i like the soft top the best of the three. Doesnt hurt that its the kiddo's favorite as well. So naturally we had to take it for a drive to get ice cream! |

Categories

All

Archives

January 2026

|