|

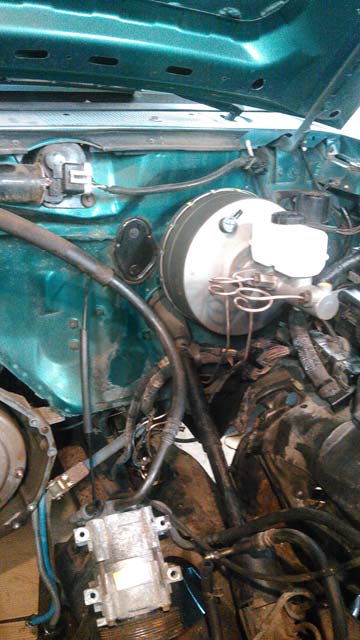

On the stand: Stripping her down OEM oil cooler. Don't have the hoses for it, not sure that im going to bother reusing this Oh noes! So the motor took a hit but aside from the cover it looks ok. Its now sitting with no oil pan or valve covers, ready to start being cleaned. New timing cover should be here Wednesday. Stock: lift + 3/4 ton swap complete: Keep in mind, there no motor under the hood yet. Once the motor goes in and the front settles out a bit, I think its going to be perfect! IMO this is how they should have looked when they rolled off the assembly line. Really like where it ended up lift-wise, and the 305s look good in the wheel well. Of course, 35s would probably look even cooler! Tomorrow will be spent doing clean-up in the garage, and then Thursday I get my wisdom teeth removed, which means this is probably the last update for the week. If all goes well, Monday I will begin on the motor! Rear axle is now complete! Brakes done and plumbed, new diff cover and full of oil Bolted it in, installed a shocks, connected parking brake cables, and called it a day. Today I dropped off the rear d.shaft to get shortened, and then rolled it out of the garage so I could do some cleanup. So here's the money shot! I shouldve built these years ago!!!! So, since I wont have my wedges for a few days, I decided to finish a shop project that I started over a year ago: Axle stands One finished both done! That said, I effortlessly rolled the axle out from under the truck, so that tomorrow (after some cleanup) I can begin refurbishing the brakes The top of the stand is slotted to accept exhaust ubolts of various sizes, to clamp around the axle tubes. They actually work really good at holding the axle in place, to the point you can roll it around freely, or even set pinion angle. New Hangar, courtesy of Dorman Springs are now installed, so this morning I got the axle mocked into place! The axle is jacked up, with the full weight of the truck on the springs. The B codes flatten out nicely; should ride nice. They get close to the overload at ride height but don't ride on them, so it should carry weight pretty nicely. The stock tapered blocks are in there currently, and need to be, but theyre both cracked so ive got a new set on order from JBG. So no snugging up ubolts or putting it on all fours until some time next week. Sucks, but it gives me time to replumb the rear brakes, and get the driveshaft shortened. Near as I can tell, it looks like the B Codes lifted it ~3", but ill have to get it on the ground so I can get better measurements. If it ends up too tall in the rear ill drop the overload. 8.8 coming out: Snow storm inbound, so I brought the 10.25 inside: One of my wedges is cracked, ill have to get replacements Moving on to the SD leafs. The fixed end is 18mm. I don't have any 18mm bolts (nor do I have an 18mm drill bit), but I do have 3/4. So ive opted to drill out the bushing & hangar to 3/4. Here's the difference in size, it's pretty minimal (.708" to .750"): Done & painted: stock pack next to the SD leafs. SD leafs "B Code" have maybe 1�½" more arch, and appear to be a tad longer. Probably going to need to keep overload, plus factory bronco block to get to 2½" lift, we'll see. Pass side bracket is in pretty bad shape. D.side was replaced by previous owner, but this one is shot & needs to be replaced Entire d.side frame has now been needle-scaled, wire wheeled & painted: If it snows tonight/tomorrow like theyre saying, ill be home clearing driveway. If not, ill be at junkyard with a buddy looking for stuff. Either way, there wont be any progress tomorrow. Hoping Friday I can get pass side frame stripped & painted. New shackle hangar arrives Friday, so im hoping Monday to install that plus hang leafs, we'll see. ...and now to delete the 4WABS. Chop up some brake lines Then remove pump & bracket the 'brains' of the operation and a ton of wires! Weve got to open up the harness that goes to the ABS ECM The 4 loose wires get spliced together to complete the speed signal. The rest of em in my hand? Useless! Yup, that looks way better. Weight reduction! And now for Phase Two: New master cylinder & booster for a '96 F350 a spool of Copper-Nickel brake tubing ...and shazam! No more 4WABS! That pretty much catches me up to today. I went to put tires on the front, and realized the chevy wheel studs are too short! Hoping I saved the studs from the F250 I parted out, otherwise ill be buying 16 new studs. Im gonna do some general cleanup in the garage tomorrow, and see if I still have em. Odds are I wont have time to swap the studs until next week. Next week's plan is to lift the rear & swap the 10.25 in., and then do a ton of bleeding to the brakes. At least, that's the plan anyway. I took some time away from working on the truck, to source all the parts to put the 351 in. Which I now have. Add in some other things along the way and I lost a bunch of time, but still, progress! lift kit installed: D50 stub shafts in place front end complete! stock pitman arm, next to a 4wd F250 arm All new Moog TREs. Instead of using bronco TREs, these are the ambulance prep Van TREs. Beefy. Got a TTB coil to compare the Superlift coils to. Yeah, something isn't right Talked to JBG. They said every set they have is made the same way. In agreement they wont work. So I shipped them back today for a full refund. So now I need coils for the front. Well, since I got those SD leafs from Steve I said screw it, and ordered the 2.5" kit from Tuff Country. So yeah, TTB is back out Sucks because i could have had the front end done today, and now im gonna have to wait until next week I guess, when the kit arrives. Thinking for now ill start removing the 4WABS. TTB is hung once more! Not shown in that pic, is the 4.10 D50 chunk bolted in, along with the front dshaft hooked back up. Chevy vs. Ford stub shaft: (Ford on top) D.side shafts installed, modified knuckles with new balljoints, adjustable camber bushings, and the chevy spindle Bam! 8-lug Then I got stalled out. Not sure whats going on here. Here is my brand new Superlift leveling coils from Bronco Graveyard. This pic does not do it justice; the lower coil retainer will pull right thru the bottom wrap on the spring: Its as if the coils were made wrong. I guess ill have to call JBG Monday and see what they have to say. |

Categories

All

Archives

February 2026

|