|

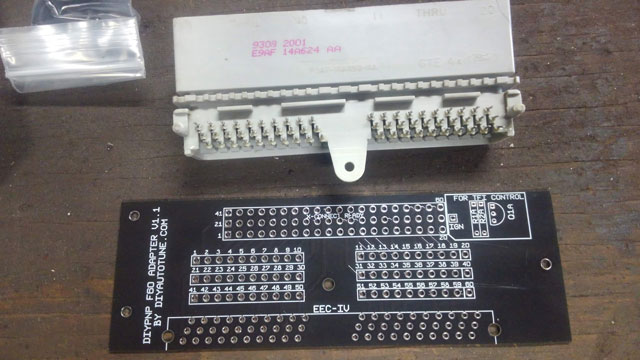

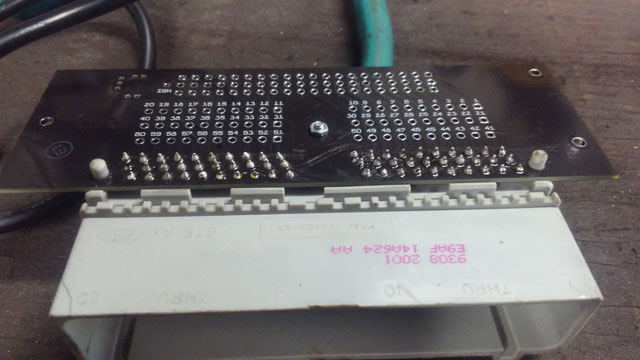

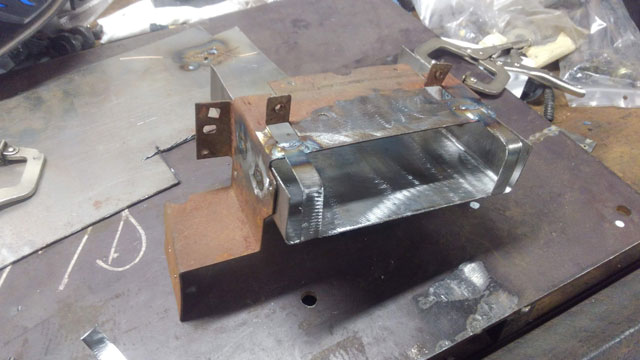

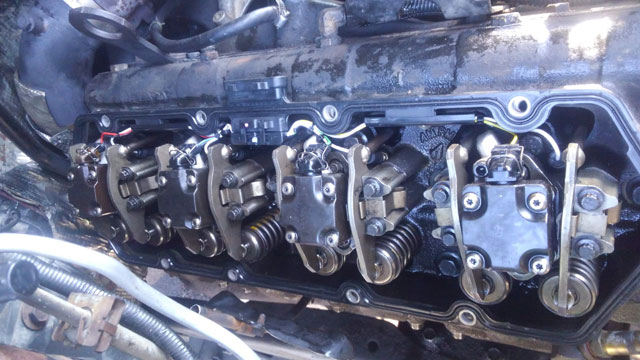

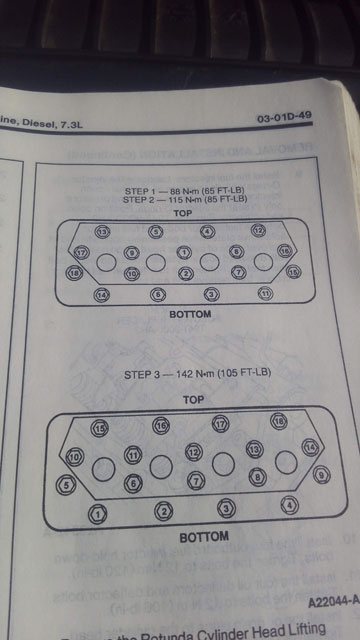

So, the end result here, is that it runs. So i installed most of the under-hood harness ( i believe all thats left is to do the alternator & starter wiring). I put in my radiator and hoses, and box + intake, and the rad overflow bottle. I also reinstalled my trans & p.steering coolers: Found a place to mount the remote trans filter too: Im also in the middle of working on the interior. I cant install the kick panels until all of the wiring is done and i verify it runs. But i can finish the rest of the interior, which is what im working on currently. If all goes well, i actually expect to have most of that done Monday, so there should be another progress update early next week! Man, its been a while! With schools closed due to sars-cov-2, and the decimation of the aerospace industry wreaking havoc on my wallet & budget (honestly, im lucky to still have a job at all), not much has been accomplished on this thing this summer. However, thats not to say i havent made any progress; i actually have but its been slow and scattered. Ive completed a few tasks now, and im hip deep on several other parts of the bronco right now. The point where im at, just about everything im working on has some form of impact on other areas on the truck, so ive elected to wait until now to post progress, since it will make more sense to focus on individual tasks as opposed to scattered updates from all over the vehicle. That said, when we left off, i was working on relocating the ECM. With that done, the next step was the wiring harness. So, heres what i came up with. The bracket i build for the ECM goes where the ABS ecm and internal amp used to be. I finished that, and bolted it to the dash frame: So now ive got to get the wiring harness to reach it. I really didnt want to cut the wiring harness and extend it though, i wanted to make an extension, this way if this doesnt work out, i cant just remove it and go back to 'stock'. Also, i love doing things the hard way, and building an extension is way harder! So when searching some way to build it, i found DIYautotune, who as it turns out, makes kits to do just that! Really, theyre for building in piggyback support for aftermarket EFI and other stuff the mustang guys do, but itll work for me! It comes as a kit you need to build yourself: It comes with a PCB, and a connector off of an old ECM I had to solder the connector to the board, and it has 2 output connections for each pin on the board, so you can splice into every wire w/o having to cut any. So i got my soldering station set up, so here we go! connector soldered to board: Attaching wires: all done! Case assembled around the connector/board: I numbered all the wires before closing everything up, so id know which wire is which. Triple checked everything, and i even found a source for new pins to crimp on the end So here she is, all done and taped up! So with that done, all that was left to do, was install the ECM and harness into the dash! And finally, after all this time, the dash is reinstalled in the bronco! Couple months later, the bornco is still handling like a champ! Wish i flipped the steering sooner. Tires are wearing so much better now too. So ive hard the hard top off since memorial day, and the XL rear cardboard panels are getting a bit rough: I cant find XLT rear panels anywhere, so i went to the local scrap yard, and found a huge sheet of 1/4" thick black plastic for $20! So i made my own: Laying out the second panel. The sheet was just barely big enough to make both: cheapy sound deadener from Amazon: First panel installed: I used the rear speaker grills out of my '88 since the cardboard panels didnt use any. I still need to find another pair because sooner or later these are going to end up back in the '88 again! ...and both done! Im pretty happy with how they came out, altho if i ever find some XLT panels im still gonna get em. With the little dude about to turn 3, i figure now's the time to get him his own ride! Let the madness begin! Picked up the bronco this morning. Handles really nice with good tires up front. I was really close on the alignment, and now its perfect. Passed insp with flying colors too, so we're good to go! aka "Fixing" the Steering. So ive been chasing alignment issues. Basically, the theory is that the F250 pitman arm doesnt drop enough for the 2.5" lift, and its causing camber in turns. Truck looks good on a rack, but continues to wear the front tires. The obvious solution is a drop pitman arm. But thats too easy! So lets make it more complicated! Steering angles before we started: So i bought some Ford tie rod sleeves from Sky Manufacturing Hole drilled out to 7/8", sleeve going in with some red loctite: tie rod's new home: Check those angles, and that ground clearance! Piece of cake, right? WRONG! Now the tie rods hit the sway bar. So, here we go! Cut the end links in half. I extended them about 1.5" using 3/4" steel rod; i thought i had a pic but apparently i dont. Endlink halves reinstalled, but on the opposite side of the bronco. 8" piece of 1" tubing to extend the link. Its crazy, but the way Ford made the bar, it totally fits just fine like this. Decided to drill/bolt the 3 pieces together: ...and just like that, sway bar disconnects! New poly bushings.... ...and done! Bronco needs an inspection, so while its there im going to have them double check my driveway alignment, see how far off i got it. Only went around the block and that was before re-adjusting toe, so i cant give a final opinion on if it handles any better/worse yet. I got the diesel done just in time for everyone to be quarantined for COVID-19. Schools & daycares are closed here, along with "non-life-sustaining businesses", altho neither my job nor my wife's fall under that umbrella. So now i hang out with the little guy after work while she is working. Thankfully no one is sick, but for obvious reasons, free time, and my truck budget, are severely limited. No roll cage this year, my new goal is simply to get it back together and running, and we'll go from there. So when we left off, my next move was to put the wiring harness and dashboard back in. The donor body had a blue dash, my original dash is gray, and im going with the charcoal! So ive got 3 dashboards laying next to each other in the garage. Im reusing my original '88 harness, so now my harness has been swapped over to the charcoal dash: Normally this would be a simple swap, and id have the dash in by now. But, why make it easy, when you can over-complicate it? So im moving the ECM. I need the space in the kick panel, so i went on a quest for a new place to put it. Staring at the blue dash, i got to thinking about this: Thats the ABS computer, the internal amp for the Premium Sound radio option, and the door chime. I dont use any of them, which leaves some free space in the center of the dash: So the gray dash is stripped and in rough shape, so lets go look at that one. It would seem if you bend up one tab, the ECM will fit in the space! So, this section of the dash frame is held in place with 4 spot welds. So, lets remove em! So i set my homebrew sheetmetal brake up, and came up with this: It fits in there pretty snug, but just in case, i made a tab to make sure it cant move: That gets us caught up to speed. Im gonna bring it into work to blast and then paint, and then i can cut the old bracket off the charcoal dash, and put this one on. Im also going to add some adhesive foam in a couple places to protect the ECM case a bit. Time is limited these days, but im hoping i can still get it done this week, i guess we'll see. Upgrading to the Superduty UVCH + valve cover gaskets: Removed the engine harness: ..and rewiring it for the SD valve cover gaskets: ...and all done! With that done, all that was left was to install the harness, batteries, fender liner, and throw some fluids in it! So i got all that done today, purged the fuel lines, and got her running! ...Then i went thru the yard, and filled the bed of the truck with downed branches from the winter So i figure ive got a good weeks worth of work of cleanup to do, but i expect to be working on the big bronco again before the end of the month! Made some progress this morning, before the weather turned sour. Exhaust manifold in, along with up-pipe, which you totally cant see, but its in there! check these rocker arms! Valve train installed. Down-pipe is reinstalled too. All new orings and washers on the injectors: I got all the injectors reinstalled, but by then it was raining pretty heavily. Hopefully tomorrow its a bit dryer out! Head! ...and all the torks! Supposed to be nice and warm tomorrow too, so hopefully that rain holds out and i can get a bit more done! Went OEM on the head gasket, and the head bolts. Considered studs but theyre major $$$, i dont really need them, and they cut all my OT at work, so..... |

Categories

All

Archives

February 2026

|