|

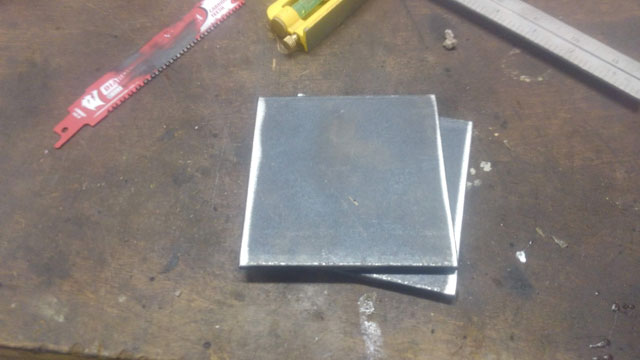

The parts pile has grown: Theres really not much left to remove at this point: So, one of the things i would like to run, is the OEM oil cooler. Thus far i have been using a remote mount unit with a smaller filter due to a lack of free space. So before i pull the block out, i decided to see what it would take to get it to fit. So this is the '95+ oil cooler. Water cooled. It fits in pretty tight against the block, and intersects the lower radiator hose. This is pretty much the orientation when installed on the motor. The oil filter ends up sticking out forward, under the belt drive, where its pretty easy to access On the right is the OEM oil filter stud, if the filter is threaded directly onto the block. On the left is the bolt & adapter if youre running the OEM oil cooler: Warning: this next pic is pretty terrible. The big block oil cooler will not clear the small block engine crossmember, altho we already knew that. The question is, what do we have to do to make it fit? Unfortunately, it looks like this entire section will have to be removed: In the long run, i feel running the oil cooler would be the best solution, so once the block is out, im going to clean the frame, and see what i can do, to make this work. Stay tuned! Ok, were making progress here: The driver head/header is now off. I still need to separate these, but on this head its only 2 bolts so it should go easier. Same thing with this header; if the set is reusable this AIR tube will be removed: I was looking down into the block, and the cam looks rough. Probably just going to replace it: Before i pull the block though, i was to experiment with this: Thats my remote oil filter mount, with the hoses for the ram assist running down thru the hole for the oil filter. i have the late model oil cooler, and it fits pretty tight against the block. Im curious to see what it will take to get it to fit in the small block engine crossmember. If its only requires some minor mods to the frame, then i might do it once the block comes out. F*cking finally! This was not an easy task to do. I actually had to sneak the sawzall down next to the header and put a small slice into the frame so the header would come out, w/o unbolting the body mounts: Its very minor, but i intend to clearance this area a bit more and make it look nicer, once the engine is out. Moving forward, i succeeded in getting the header off the head: I am a little concerned for the condition of the header flange however. This still has old gasket on it that needs to be removed, but it still looks a bit rough in my opinion: Considering headers for a 460 are pretty expensive, i think its worth my time to clean them up, sand blast em, and see if theyre gonna be ok to reuse. If so, im going to remove the tube for AIR, since the broncos dont use that emissions system anyway. Ok, so, i made a mistake many years ago, that im correcting today. Way back in '05, when i was still in the process of doing the oneton swap, i made a custom transmission crossmember. I made is a single piece, super high clearance. It worked well, but it was a pain to install/remove. The last time i installed it, was before i had the exhaust system built for the 460. Well, turns out there wasnt enough room to remove it, so i had to cut it in half to get it out: I figured now is the time to make it two-piece, before i remove the exhaust system entirely. So i cut up some 4" flat pate into squares, and made some flanges to bolt the two halves back together: Now that ive verified that it still fits in the truck, i can remove the exhaust: From there i pulled the radiator & electric fan, and then started stripping the accessory drive: Pulled the intake to make it easier to get the motor out. The distributor is frozen and wont come out Fast forward 5 days. The headers were installed with stainless ARP bolts. These are the only ones i got out. That's it. The rest seem to have welded them to the heads. Its a bit of an issue. At this point i may have to pull the heads with the headers still installed. So the pile of parts on the table is starting to get big: The NP203/205 doubler is out: ...and the C6 is as well: Hopefully next week i can get the engine out, and we can find out just what went wrong! Ok so the very first thing i wanted to do after my junkyard trip, was to get my headliners installed, before i ended up wrecking them in the garage! My front headliner was pretty saggy. It was already starting to droop, and then driving around for a couple summers with the top off definitely made the situation worse: Being an XL, this thing didnt come equipped from the factory with the liner in the hard top, nor did it have the cargo light (the light is suspended by the liner itself). All it has is this round black plug: Luckily if you remove it, it exposes the plug for the cargo light so no wiring required to make it work, its all already there! I dont really have any progress pics, but this is a pretty easy swap. In the rear the liner is actually held up in place by the rear window seals, so you can remove all the trim & even the top w/o the liner coming down. This also made the original removal in the junkyard a little difficult, but the install went quite easy. The finished product looks pretty good too! I have not installed the rear cargo panels yet. If youll notice in the pic below, the arm pads from the little storage pockets are missing, so i still have to source a set of those. I also havent swapped the glovebox door yet; i have the lock removed, but i need to drop it off at the locksmith to get rekeyed and havent done so yet. Hoping to get both of these done soon though! Went to the yard yesterday with a buddy looking for parts, and scored! Like 3/4 of the interior out of a 95ish bronco: Both headliners, the locking glovebox door and the rear cargo panels are all going to go into my 96 bronco once i get them cleaned up (and find replacement armrests for the panels since theyre missing). Also found a 95 F-Superduty, which still had the hydroboost unit! Got the master, hydroboost unit, one of the high pressure lines (the other was cut), the pedal assembly, the instrument cluster and the intake hoses (7.5L) for a whopping $58! So after 'finishing' the resto on my '88, (plus countless parts trucks & junkyard trips) i ended up with boxes of OEM hardware. Interior, body, frame, whatever. I cant help but save it! But it was super helpful when putting the 88 back together, so thats my excuse for keeping it! It was a bit of a mess though, so i started sorting it. This is just one of many boxes: Bought some organizers from HF, this wasnt enough: ...so i ended up building a frame to store them: The finished product: Built it so that it would just roll under the workbench for storage So im pretty happy with how this came out. I figure next time im working on one of the trucks i can just roll this over if i need hardware. Before you ask: Yes, every bin in every organizer has hardware in it. Took me a week to sort it all! So naturally, the night after i finish building this i pop into the lab at work to find out that with the expansion theyre getting rid of all their old cabinets! Thankfully i had driven the truck in to work, because i scored big: cabinet 1: cabinet 2, a Vidmar! Loaded with partitions & dividers: cabinet 3: cabinet 4: random free sheetmetal, some of which ive already used to build a shelf for the inside of cabinet 4: black resin countertops for cabinets 3 & 4: Anti-fatigue mat: the mother of all anti-fatigue mats, this one 4' x 24'! So now the Vidmar is now under my workbench: The other cabinets are still sitting in the center of the garage- im currently trying to figure out where im going to put them or if im using them to replace any existing cabinets, etc. Currently ive got boxes of stuff all over the place! Im kinda nuts for item & tool storage, so ive spent all week just looking at stuff & moving it back and forth from cabinet to cabinet, trying to figure out how i want to reorganize it all. Goal is to get all this sorted next week, and then its back to work on the '88! Somewhere under this mess is a t-stat intake is now off: reference pic for myself. Front of motor at bottom: This one doesnt come across well in the pic, but the pushrods are pretty rusty Exhaust manifolds are now off. This went well; there was already one broken bolt in each head, but the rest came right out This is concerning though; on the right head, the forward bolt hole for each port is cracked #2 plug broke off the second i touched it ...so did the #3. And the #6. And the #7... Rolled over. The oil pickup is pretty gross The cam is showing its age: ...so i decided to pop the #2 main cap. The bearings are pretty worn, and you can see some scoring ...which corresponds to scoring in the crank journal The flexplate is cracked all the way around too The bores dont look too bad, but i cant truly examine them with the pistons in. The crank needs to be cleaned up and new bearings. Probably just change cam at that point. New lifters, pushrods & rockers. New flexplate. The cracks in the passenger head are concerning though, not sure about those. That kind of seals the deal for me, now thinking i would be better off just using this as a core for a reman. Not sure what im going to do now, but either way this isnt going to be a quick fix. I wish i could say ive been enjoying driving this thing, but sadly i havent. Not for lack of trying of course, its just that as soon as i got the front-end alignment dialed in, i started hearing it. What started as a mild tap rapidly turned into a pretty loud knock. By the time i burned thru the first tank of gas, it was pretty apparent that my knock wasnt going away. It seems rod knocks never do. So now i have to put a motor in. Back in early March i picked this up Its another 460, this one out of a 95, with 120k on the odometer. Fired right up, idled smooth, no smoke or anything. So it seems to be a good candidate to swap in place of my tired noisy motor. Got it unloaded, and up on the stand, ready to inspect You can tell it came out of a plow truck. Started soaking the plugs & manifold bolts in prep for removal next week Popped the right valve cover, and found a disheartening surprise: Doesnt look so good in there. Guessing this thing sat for a while before i got my hands on it. Decided to dig in deeper. I like this style of oil cooler as opposed to the older oil-to-air cooler, but ill have to inspect it, and see if theres rebuild kits for them She's looking a little rough on the outside: The water pump, while looking awful, appears to be an OEM piece. In fact, everything appears OEM, including all the parts that have obviously been replaced. Im pretty sure this truck was being maintained by a dealer, right up until the frame rotted and broke The oil does not look good. I suspect coolant contamination but cant confirm. Timing cover coming off Chain is at the service limit and should be replaced. But the condition of it is disappointing, as is the condition of the coolant passages: Cant see much from underneath. Next weeks plan is to pull the intake & heads, roll it over, and inspect the bottom end. Hopefully i find things in better shape down there, because im thinking this motor might need a rebuild as well. Oh well, at least it was cheap. |

Categories

All

Archives

February 2026

|