|

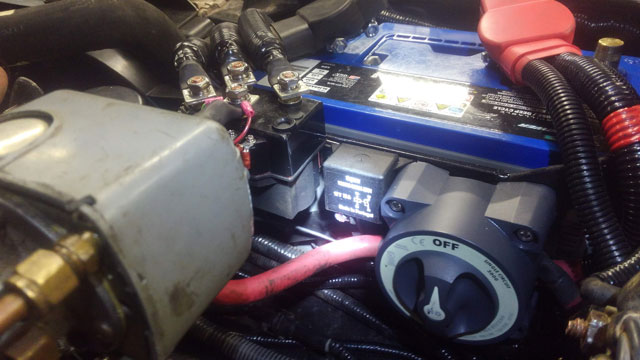

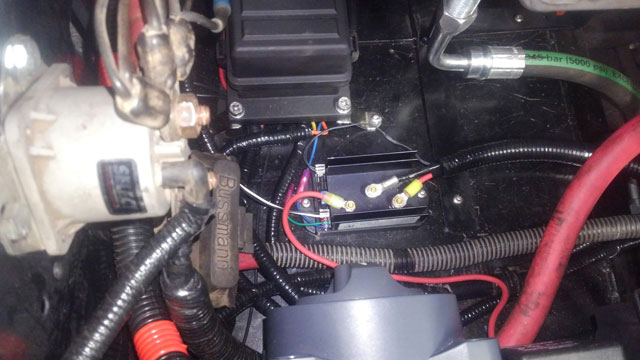

So the next big part of the wiring job is the electric fan. I opted for a can controller from DC Control, specifically his model FK-75 controller. Its a PWM controller, rated for 75a continuous duty, and fully adjustable. For those that dont know what PWM is, its pulse width modulation. The short version is, it doesn't just turn the fan on, it pulses the power on & off, to control how fast the fan spins. This means you can run the fan at any speed you want, and it also means theres no big load on the electrical system when the fan starts. Most OEMs are now going this way for their electric fans, and its all over the industrial world as well since its so effective for motor control. Anyway.... So im running the windstar fan, which i installed on the radiator some time ago: Its 2 single speed fans that Ford ran in parallel. Its not a high/low thing. Fan controller: Came with everything required to wire it up, so lets get to it! Ok, first off, i want the fan to turn on when i turn the key on. I dont want to have to turn a switch on on the dash, because that also means i can forget, and overheat the engine. Youd think youd remember, but my old fan was wired that way, and i definitely forgot once or twice! This meant i needed a relay capable of handling 60+ amps continuous duty. Well, i found one, and its more affordable than you think Obtain Surplus: 75a relay Conveniently, it fit right between my winch disconnect and the contactor. Perfectly. I didnt have to drill any holes, its the perfect spacing that its held in place by the screws from both of them: fan controller mounted: Fans wired. You can see the temp probe wiring poking out of the loom: Temp probe. Its a delta temp probe that installs right in the radiator fins, and it is remarkably quick to respond to temperature change: This was an interesting picture to take. I had to drill a small hole in the fan shroud for it to pass thru, and then wedge it into the fins. Then hold the fan away with one hand and try to snap a pic with the other! Everything all done being wired & loomed: So theres an input for A/C. When the A/C is on, it automatically turns the fans on at 50%. So i tied into the output for the pressure switch, this way it only spins up if the A/C is actually working. Which currently it isnt! ...and there it is, the whole thing done! So there was nothing left to do but test the system. And it works! So, if you were paying attention, you noticed an LED next to the switch for the winch control. Well, its for the electric fan: This is a feedback sensor for the fan. When the controller first turns the fan on, it will blink red. Then, it will start off green. As the fan ramps up in speed, it will turn yellow and then eventually red once its 100%, so you always know how fast the fan is spinning. So, i ran the truck for almost an hour the other day to test it, and its amazing how well it works. First off, the PWM is amazing; even at idle the volt gauge doesnt even flinch when the fan turns on. The controller ramps the fan up to speed and then turns it back off since at idle, it cools it off very fast. Even with the engine held at 1100 RPM, the fan doesnt run full speed, which is quite promising. The controller is adjustable +/- 35º, so i can fine tune it if i need it to turn on sooner or later, but my preliminary testing seems to show that its gonna work just fine. So, this concludes the wiring portion of this project! Im taking the next week to get some projects done around the yard (and cleaning the garage). Then, the truck goes up on jack stands, and we will begin rebuilding the axles and suspension. We're getting ever closer to driving this thing! Comments are closed.

|

Categories

All

Archives

February 2026

|