|

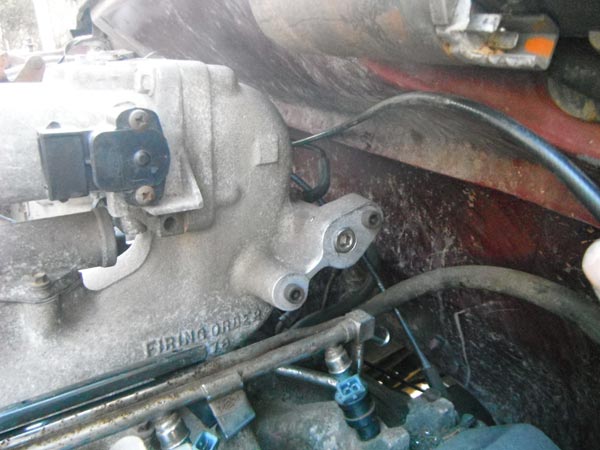

So with the help of an easy out, i got the oil filter adapter out of the 351 block, and screwed it into the 460 block. Then it was just a matter of installing the remote oil filter adapter. I went with one from Summit Racing, because you can rotate it to aim whichever direction you want. Made it a ton easier to figure out the routing. Remote filter bracket on block. There are crimp-on AN hose fittings on it so i could see which way i wanted to angle it on the block. Bracket for the oil filter housing Where its located ...and installed Fits there nicely, with plenty of room to get to the filter. And its nice & stable too. I have my AN lines half-made- i put a 90º on one end so i could run them under the truck and measure for length. Now that i have that figured, all i have to do is crimp the other end on and theyre done. Then tomorrow morning ill just have to put em in, add oil, and (hopefully) start the truck! Once i know it runs, ill continue working on the airbox. Not a whole lot of progress has been made. Transmission is done & filled, so is radiator & power steering. I think i figured out my airbox, seems it will just clear the hood (the stock box) so im ok with it where it is. But i have to get it just right so the ductwork will clear a York, which is proving to be difficult. I had to remove my overflow bottle so i could make room, and also had to move my line lock, which meant i also had to re-do my OBA manifold as well. Now its looking like my remote oil filter will have to go behind the headlight, not sure where else it will fit. At this time i have absolutely no idea where my overflow bottle will go, i think im gonna try to get a small one that hangs off the radiator (wasnt that Taurus or Mark IV or something?) If it stops raining im going to try to get the oil filter set in place so i can get lines made to atleast fire it up, but its supposed to rain all day today and tomorrow so i might not get anything done. After that, im guessing another full week of work atleast before i figure out where everything else will fit, and how to install them in those places. So here was the plan: The airbox would fit there. I even moved the line lock towards the firewall, and replumbed the OBA manifold to do it. But, i realized today that wasnt going to work, and here's why: There is no way i can fit the York there. The York has got to go there, and its got to lay down in that position, its the only way to get it to clear the hood with any room to spare. So i devised this idea today: Here's what youre looking at. 86 302 intake tubes coming off throttle body, to OEM 460 plastic intake crossover pipe thing which then goes to econoline 460 airbox tubing, and then the factory bronco/F-series airbox. Its a little longer than the factory design, but its the same diameter as stock & clears everything, including the hood. The charge cable for the alternator was already barely long enough, with the airbox there i will definitely need to lengthen it, but putting the airbox here will solve all my other problems. Hopefully i can get that to work, but i probably wont mess with it till monday. If it does work though, it frees up all the room i lost on the other side, meaning i can put my overflow/washer fluid reservoir back, as well as leaving me room for my oil filter housing, and should leave enough room for when i eventually add a line lock to the front brakes too. So im really hoping i can make this work. As for the oil filter, my remote filter brackets came. What i did not realize though, is that i need an oil filter adapter from an engine that did NOT have an oil cooler. Fortunately, the 302/351/460 all use the same one (the nipple threaded into the block), so if i can unscrew the one out of the 351, i can use that. If not, ill order one from Summit. Im hoping i can get mine out, because as soon as the oil filter is plumbed, i can start it! Got a little bit done yesterday. Reinstalled the doubler shifters, and added a tab to help keep the bolt from working loose Fenderwells reinstalled, with a little mod for more airflow 99% of the wiring done, just got to hook up the electric fan & OBA My airbox situation. Cant reuse the stock box, no room for it with the wheel wells tubbed. Still working on this one. Today im going to drop the trans pan & change the filter, then i can fill it up. Hook up lower rad hose, and fill that up too. Have to add fluid to the power steering too. I need to lay my York over to clear the hood but i have the wrong one, so i need to go junkyard hopping for one. I can whip a bracket up for it using mine as a template, but cant use mine so in the meantime im running the a/c idler pulley in its place. I need to put the manifold back in, thatll happen today too. Had to order remote oil filter brackets, wont be here till friday. Once they arrive and i set that up, i can start the truck! Small block starter on left, big block on right Ford Racing 9mm wires Ok, this was a WTF? moment. This is the wire for the 02 sensor. Instead of running down the bellhousing, Ford wanted the wire to run down the wheel well, inside the same loom that the starter's power cable runs through. So, in order to get there, this is the path it had to take: Heres the full length of it. Stupid long! Ford actually added an extension to the wire to make it longer, but both ends of it are female, meaning if you remove it, you cant plug in the O2 sensor. SO the obvious thing to do, is splice a female plug onto the end of the first harness, and delete the extension. That was a simple one. I chose to keep the main cable the same length it was before. Heres why: the first cable all by itself was the perfect length. Dunno what Ford was thinking when they laid it out the other way. I also hooked up the radiator, trans cooler & power steering cooler. Got a shorter belt for the alt since the smog pump is gone, and put the a/c delete pulley on so i could put the orig belt back on there. I have to get a different York, i have a left hand suction and need a right hand suction so i can lay the York over in the horizontal position so it will clear the hood. I rerouted the ARB & axle vent lines so theyre not so close to the header, and reinstalled a ton more wiring. Also hooked up the trans vent since i forgot to do that. My neighbor came came over today to help, so lots of progress!!! I quickly whipped up a half ass carriage for the floor jack, that ended up working really well to put the doubler back in: (Before you ask, yes its welded to the yellow cup, that was an extra one i had for the floorjack) Then while he was installing the doubler mounts, i did some wiring harness work. The 'secondary' harness, which is for the injectors, TPS, ECT & IAC: and the main control harness + ECM installed: then we installed the anti-wrap bar + xmember, and both driveshafts. So we got lots done today! Things left to do:

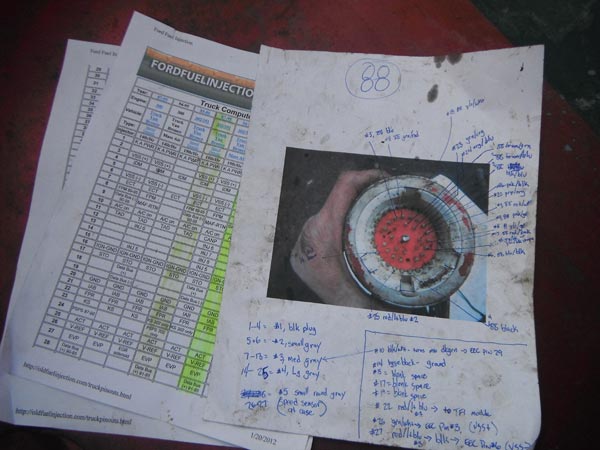

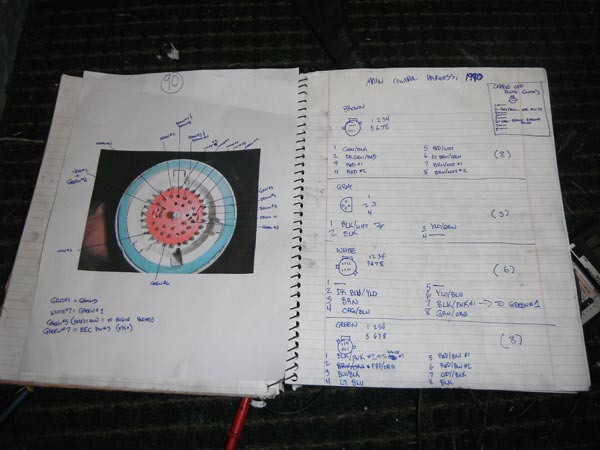

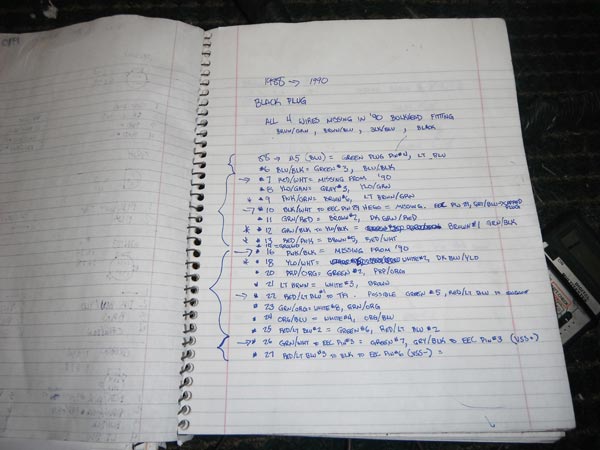

progress pics! My 200 amp 3G installed. Fits with no mods. Saginaw pump, and my York setup off the 351. Front clip! ...but wait, whats this? The intake just touches the hood when its closed. However, it looks like i can drop the pump a ½" just by redrilling my bracket. Might be able to go ¾". Im gonna drop it as much as i can, and if i dont like it, make a new bracket. Starting to look like a truck again! I didnt think i was gonna get the front clip on today. It was raining pretty hard, but it slowed down a bit, right when a buddy stopped by. So he helped me set it in place before leaving. After i got the clip bolted up, i put the hood on by myself, which isnt easy! Fortunately, the body is so thrashed that i dont need to have everything aligned perfectly, just 'good enough'! Tomorrow im going to modify the York bracket, and then probably start installing the wiring, and hooking up the radiator & coolers. Theres still tons of stuff to do under the hood, plus i need to reinstall the doubler + mounts, dshafts, & my anti-wrap bar + xmember. Also want to throw in new shocks & bump stops up front. So lots to do just yet! frame mounted pump removed While the frame was exposed, i took the opportunity to properly remove some wires, specifically for the original tcase, the HCU for the ABS, and the second fuel pump fuel filter relocated back where the pump used to be I reused the original fuel feed line to the rail (from the pump). The original return line was ~8" too long, so i had to cut it down, but now it all fits up there nicely, and its all far far away from the exhaust. Getting ready. A buddy of mine came by to lend a hand getting this beast in! We had to drop down to wood blocks to get it low enough, and then we ended up having to unbolt the cab mounts and jack it up 4" to get it to clear. After a couple hours, the motor & transmission are now in! Nice beefy motor mounts Some clearance issues. Header is pushing on fuel filter heat shield & fuel lines. Heat shield is pushing on trans shift linkage. I have temporarily removed the heat shield, ill deal with everything else soon. Remote oil filter/oil cooler bracket. Does not clear frame. Apparently the big block trucks have a bigass hole in the frame to clear the bracket & filter. There is no good way i can clock this thing, where the filter & the oil cooler lines will be free of obstruction, so im going to replace it with an aftermarket remote filter housing and not run the oil cooler. Or, cut a big hole in the engine xmember, which i dont really want to do. I tapped the port for the EGR, and screwed a plug in to seal it off. I also got the cab bolted back down, trans shift linkages done, trans lines re-installed, vacuum line for the modulator, kickdown cable, throttle cable, and all the vacuum for the motor done (except for the FPR) So, my truck, being an 88, has the dual fuel pump system. Well, the 90 p/u tank i have been running out back for the last several years, is from the single pump system so its already a high pressure pump. So the plan is to eliminate the rail mounted pump. Then i can move the filter down where that currently is and reroute the fuel lines, which will get everything far away from the header. Ok, so before the motor can go in, i need to address the motor mount issue. Well, Everyone says the conversion mounts are junk, and after seeing how beefy the OEM 460 mounts are i have to agree. So i went to the junkyard and got a pair of motor mount towers torched out of a truck. Only cost me $30 for the pair! Before you ask, yes the towers are discontinued by Ford, i looked into it. There are a couple passenger side mounts left scattered in random dealers across the US, but thats it. They also cost more than what i got my pair for. Towers, fresh from the junkyard: Excess frame removed, and wire-wheeled in preparation for paint My frame, with the small block mounts still installed Just like the big block towers, passenger side is 4 bolts, driver side is bolt (2) & rivet (4). Passenger side towers, big block in front Driver side towers, big block in front ...and installed in my frame. I saved the bolts from all 4 towers because they were all in great shape, which left me with more than enough bolts to replace all the rivets i knocked out. With this done, theres really not much left for me to do before the 460 goes in! My notes from the 88 harness. But now i have a big problem. the bulkhead fitting for the '90 harness has pins in different places. looking at the two, i see 5 pins that are not in the right spot. Comnparing the 89 & 90 harnesses, they are pinned almost identical. (the 89 harness came w/ the motor, but is butchered by previous owner, the 90 harness came with my cab) This is a huge problem. I need it pinned like the 88, for it to work with the dash harness. I see myself as having three options. #1, i rewire my 88 chassis harness to plug into the 90 control harness, and then re-pin the bulkhead connector to plug into the 88 dash harness. This seems to be the easier of the two, but now i have a custom harness so if anything happens to it ill be ****ed. #2, completely rewire the motor harness to plug into the 88 main control harness. This is gonna be a huge project because it will require grafting the 351 harness onto the 460 since the ECM connector is on the 88s engine harness. This will make it kind of like a 88 F350 harness, but is not something i want to do because it will be crazy hard to do. #3, find a engine harness from a 1988 F350 w/ 460. Somehow i dont see this as very feasible. My father has the complete Ford wiring diagrams book for a 1990 which he is going to mail to me, so thats half the battle right there. Here is what i need. I need to know the color code for all the wires that go to the tailgate on a 1988 bronco, so i can eliminate those wires from the bulkhead fitting. Those could very well be the wires that dont match up with the main control harness im using. At this point i dont know what too many of the wires are for, only where they go. I know the parts guys at the local Ford dealer, so im going to see if i can get these diagrams tomorrow. Notes on the '90: Some interesting info. Both harnesses have 24 wires. All of the similar pins in the bulkhead connectors go to the same places, and most are the same colors. The 88 has 7 wires the 90 does NOT have. The pins arent even in the 90's bulkhead connector. I suspect 4 of these are for the tailgate. The other 3 i have no idea, as of yet. Possible they have to do with the dual vs. single fuel pump setup in 88 vs. 90? I dont know yet. The 90 has ~8 wires that, while they have corresponding pins on the 88's bulkhead connector, they dont go to the chassis in the 88 harness. Tomorrow i need to ohm out these pins on the 88 harness, to see where they go (maybe to the engine or elsewhere? or possible for the dual tank setup the 90 had?) The wiring for the O2 sensor is different too. Rock Auto lists a different O2 sensor for each year, but the Ford p/ns seem to be the same? Not sure yet. The 88 has a 3-wire O2 sensor, the plug on the 90 harness has 4 wires. I think the difference is that the 90 has a ground wire in the plug, i dont think the 88 did. |

Categories

All

Archives

June 2024

|